Hardware Development

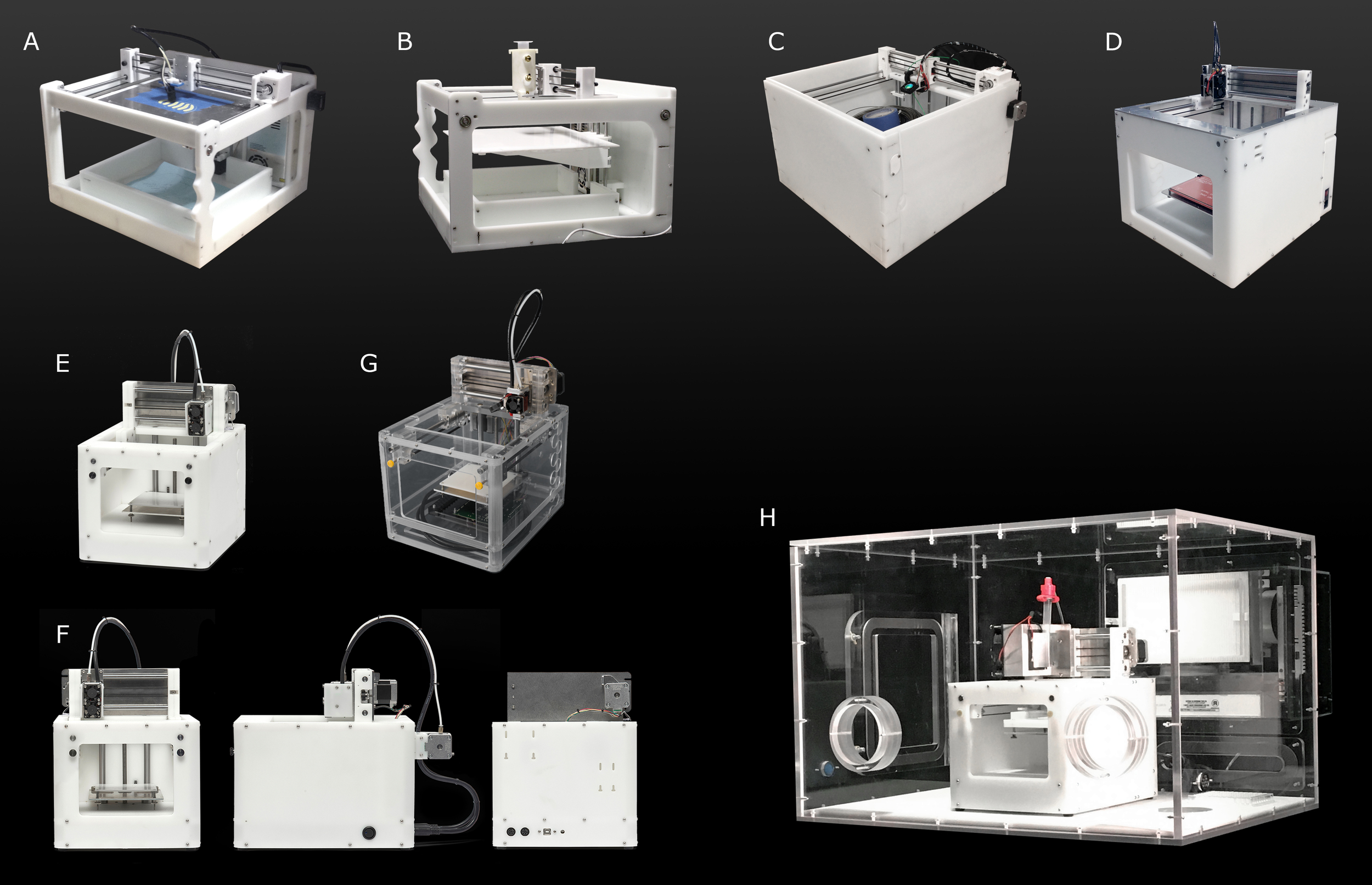

This Page is a collection of the hardware development at Jimmi from 2014-2016. We have designed, built, and iterated several versions of 3D Printers, 3D Bio printers, and other hardware for digital fabrication processes.

A: Jimmi v1.0 (May 2014) B: Jimmi v1.2 (July 2014) C: Jimmi v1.3 (Oct 2014) D: Jimmi v2.0 (Jan 2015) E: Jimmi v3.1 (July 2015) F: Jimmi v3.2 (July 2015) G: Jimmi v3.3 (Mar 2015) H: Jimmi v3.4 (Feb2016)

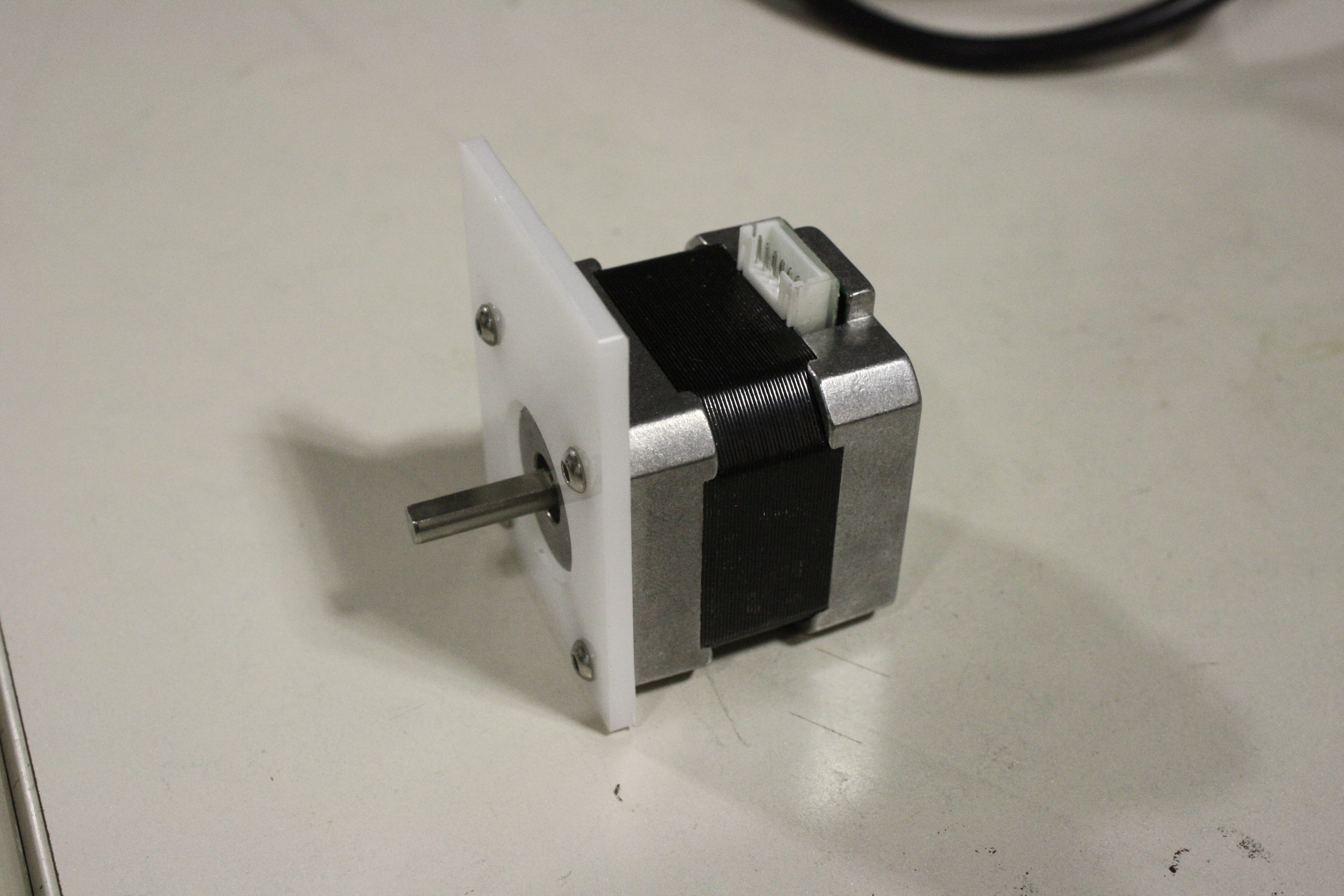

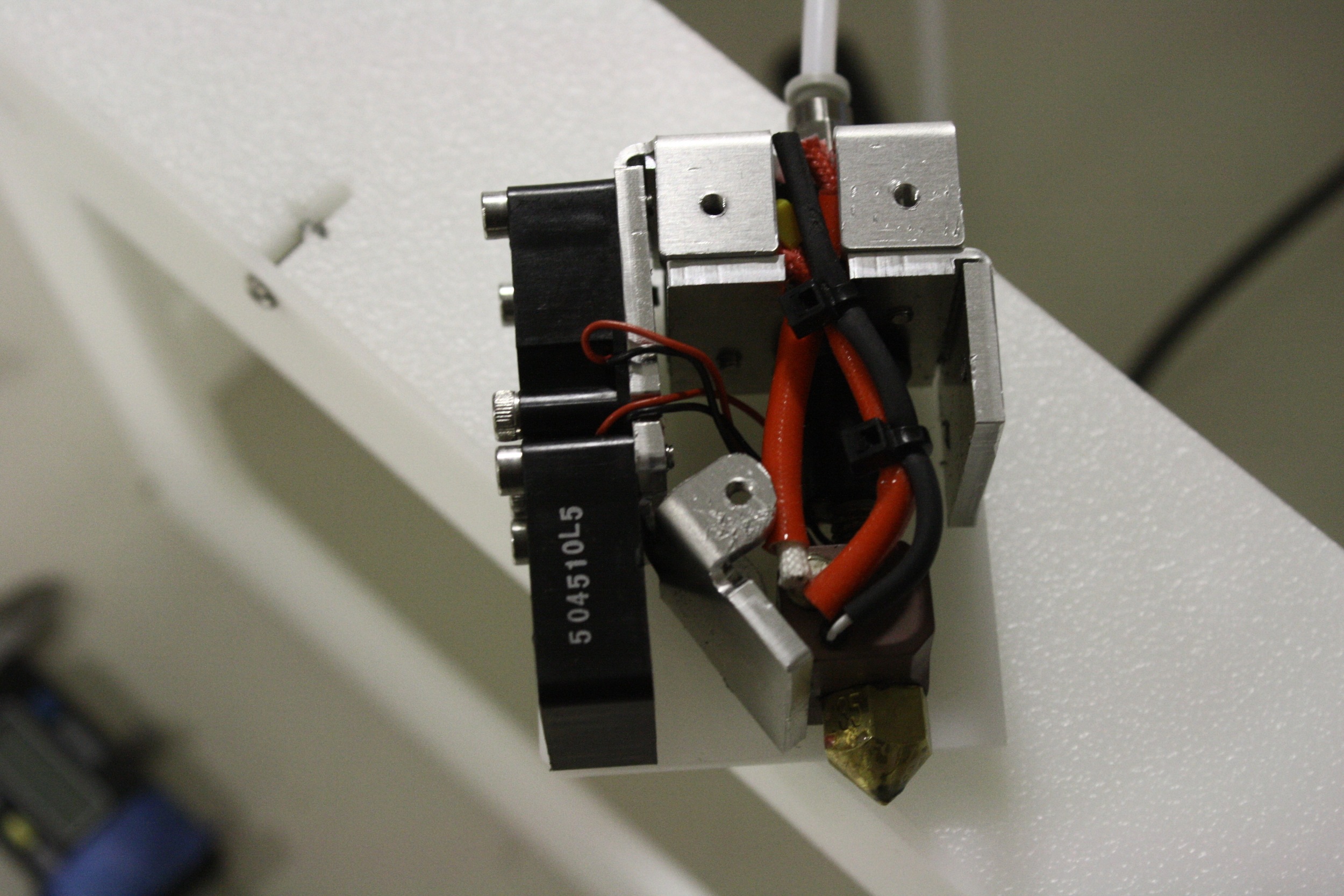

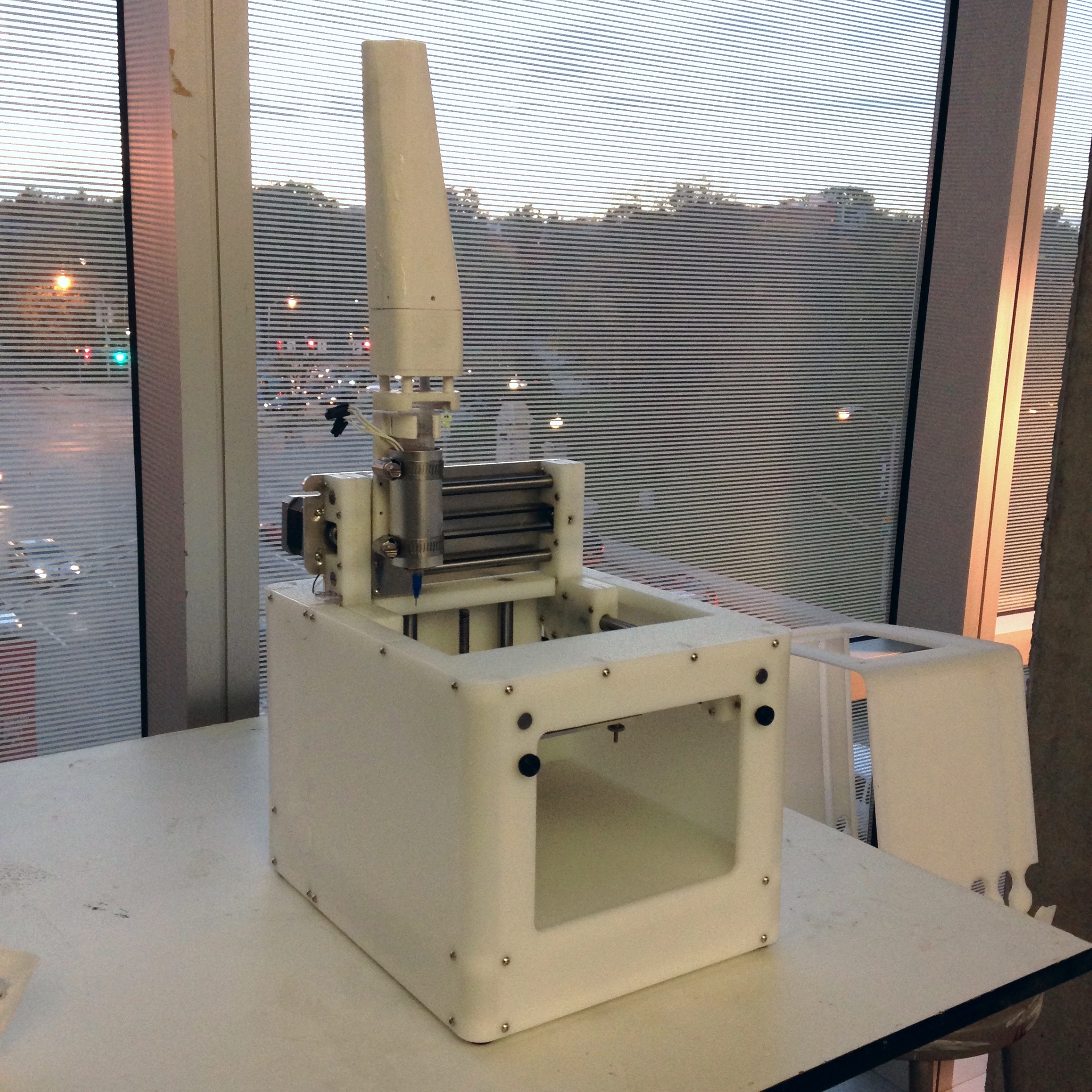

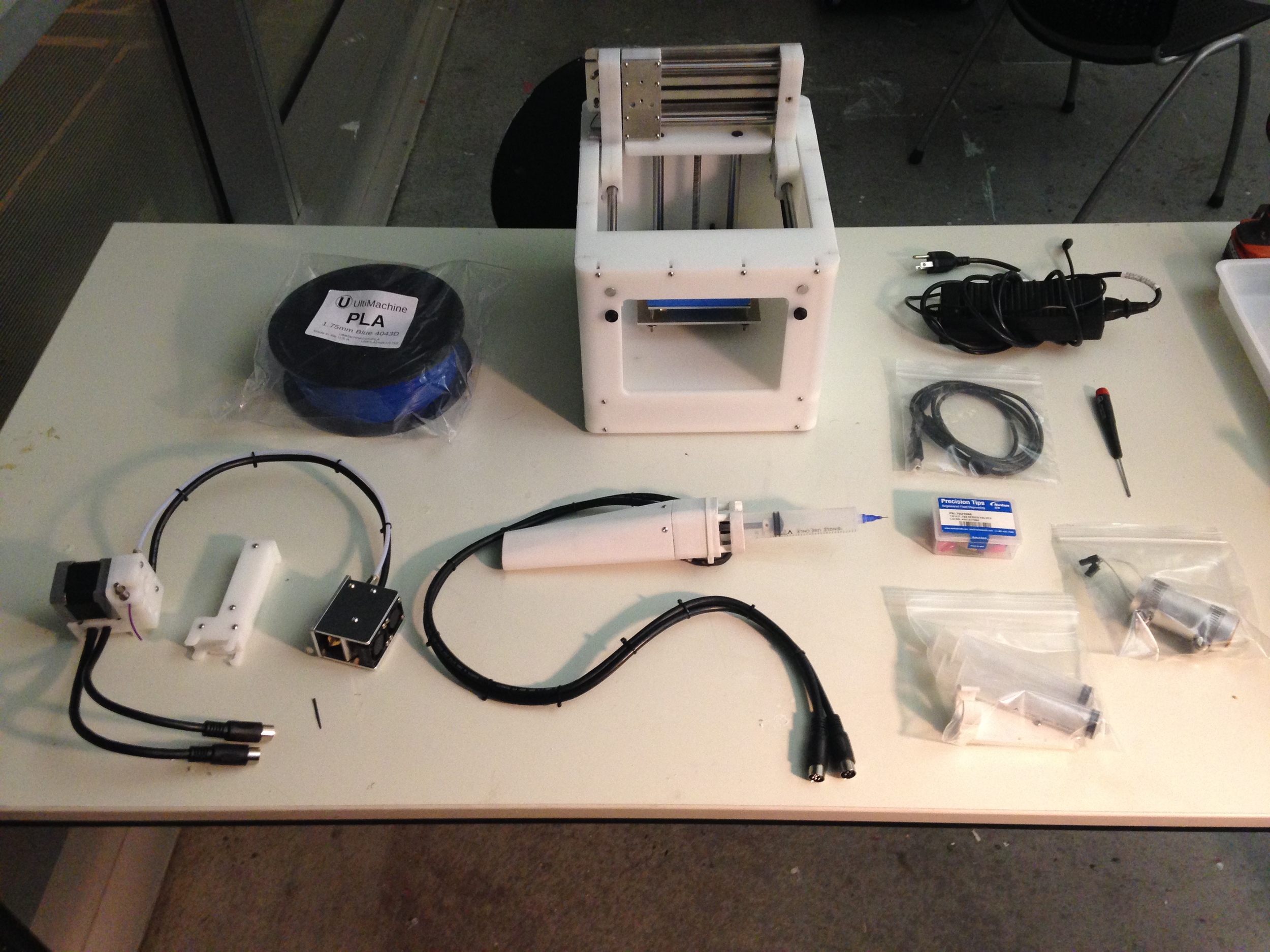

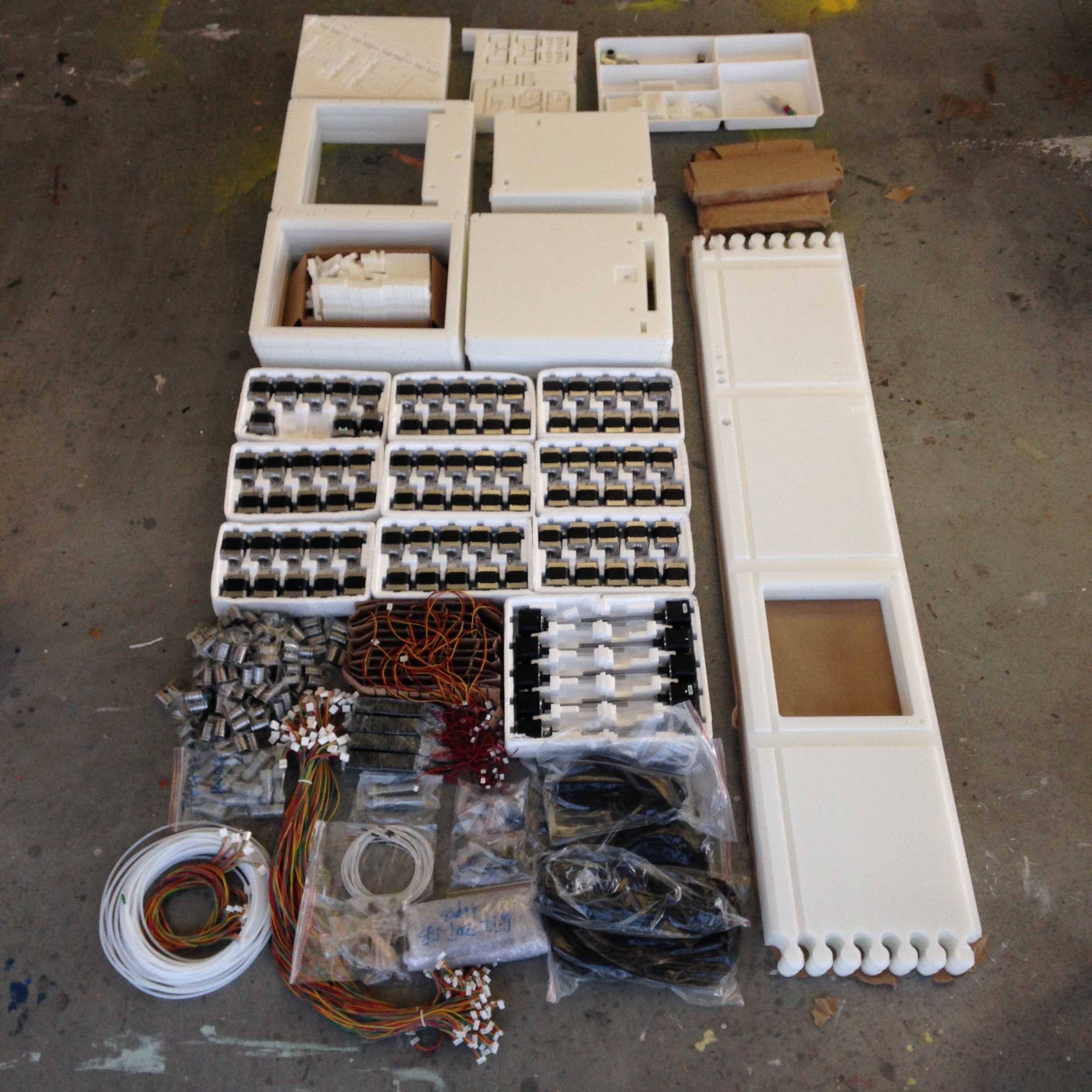

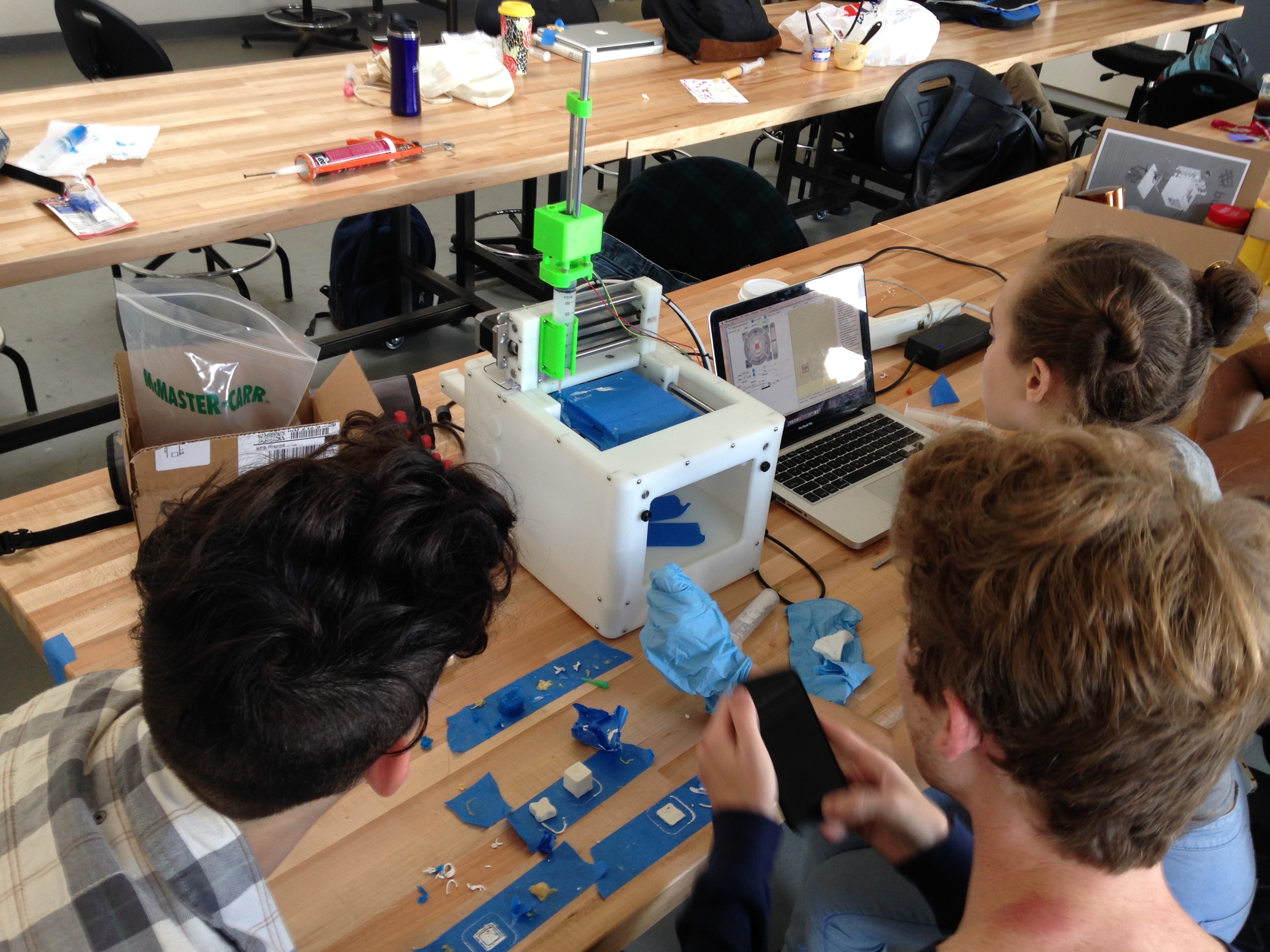

This Hardware development project began in 2014 while we were still involved in the digital fabrication lab at MICA. We designed the first Jimmi 3D printer as a platform for experimentation where we began printing with nontraditional print mediums including oil paints, foods, ceramic, and various polymers. Shortly after this in late 2014 we began planning a series of workshops to involve others in the process of building 3D printers, experimenting, and innovating new process. This soon grew into the Buildclass workshop series. These workshops were the backbone of the hardware development process. The workshops were the best way to test new hardware and uncover problems, and we designed them so that the profit from these workshops subsidized the cost of the hardware development process. We developed a lean workflow for designing and manufacturing all hardware by digitally fabricating all parts with CNC machining and 3D printing. This enabled us to iterate rapidly, develop a prototyping process that directly translated to a manufacturing process, and we avoided high overhead costs of mold tooling and other traditional manufacturing processes.

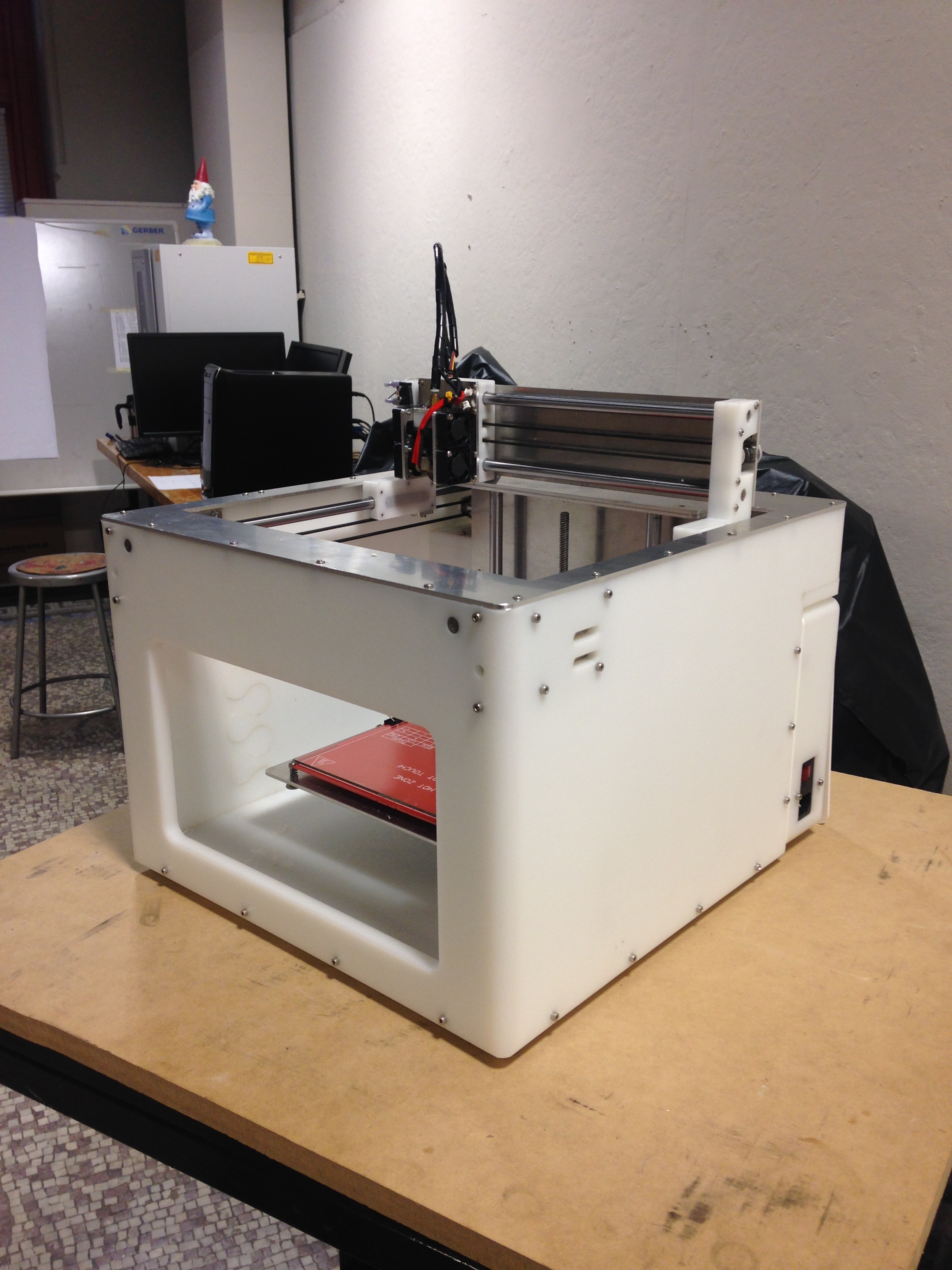

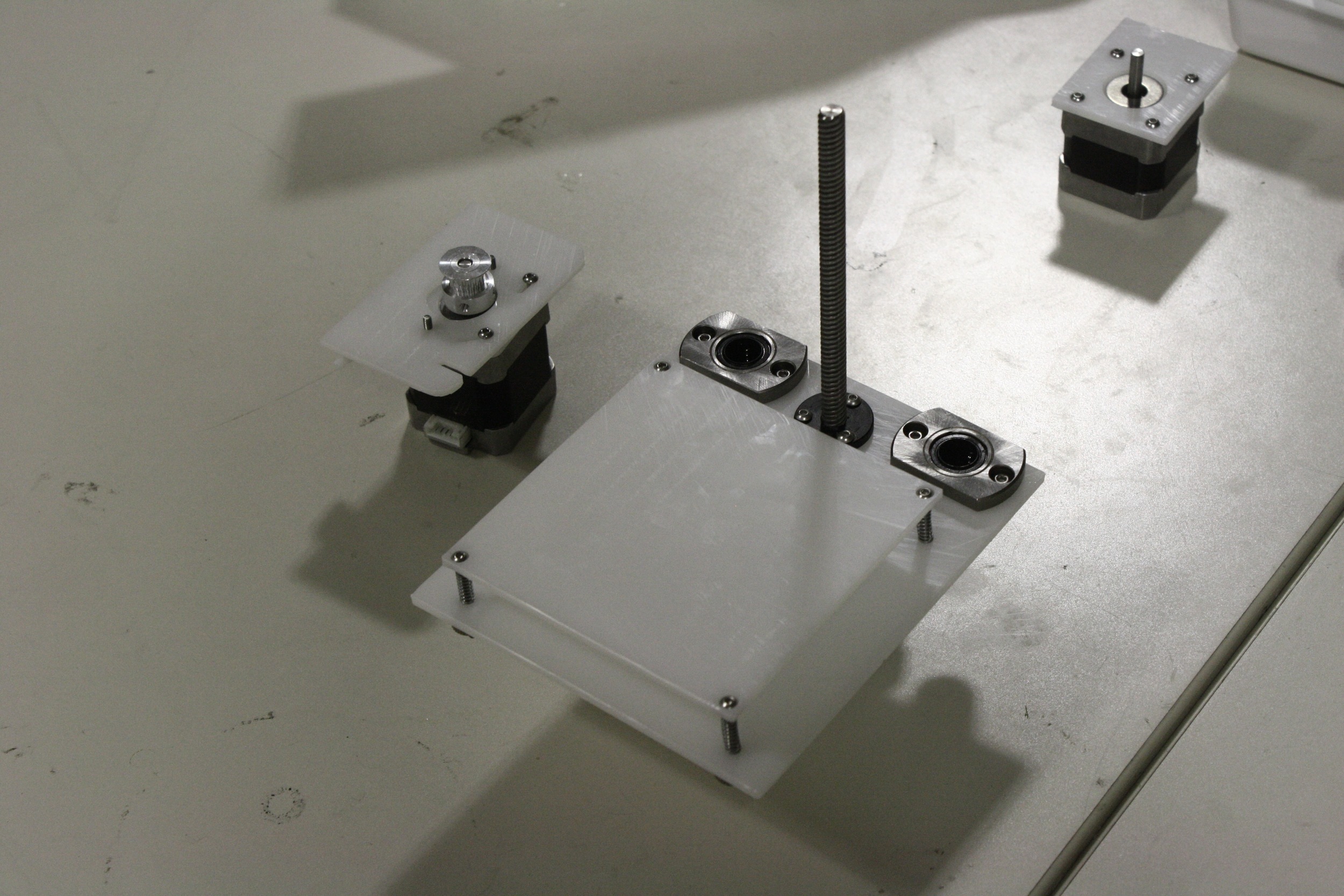

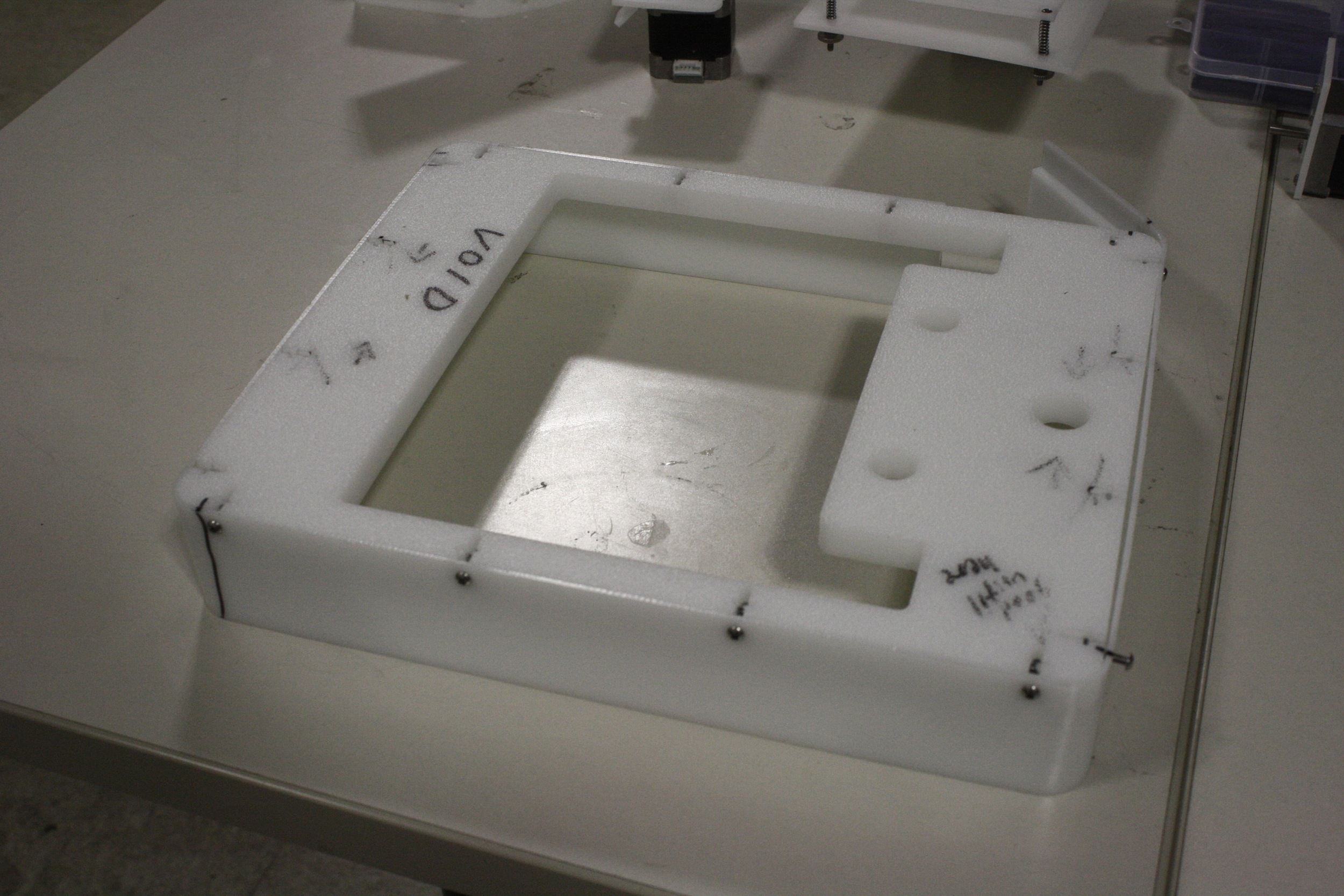

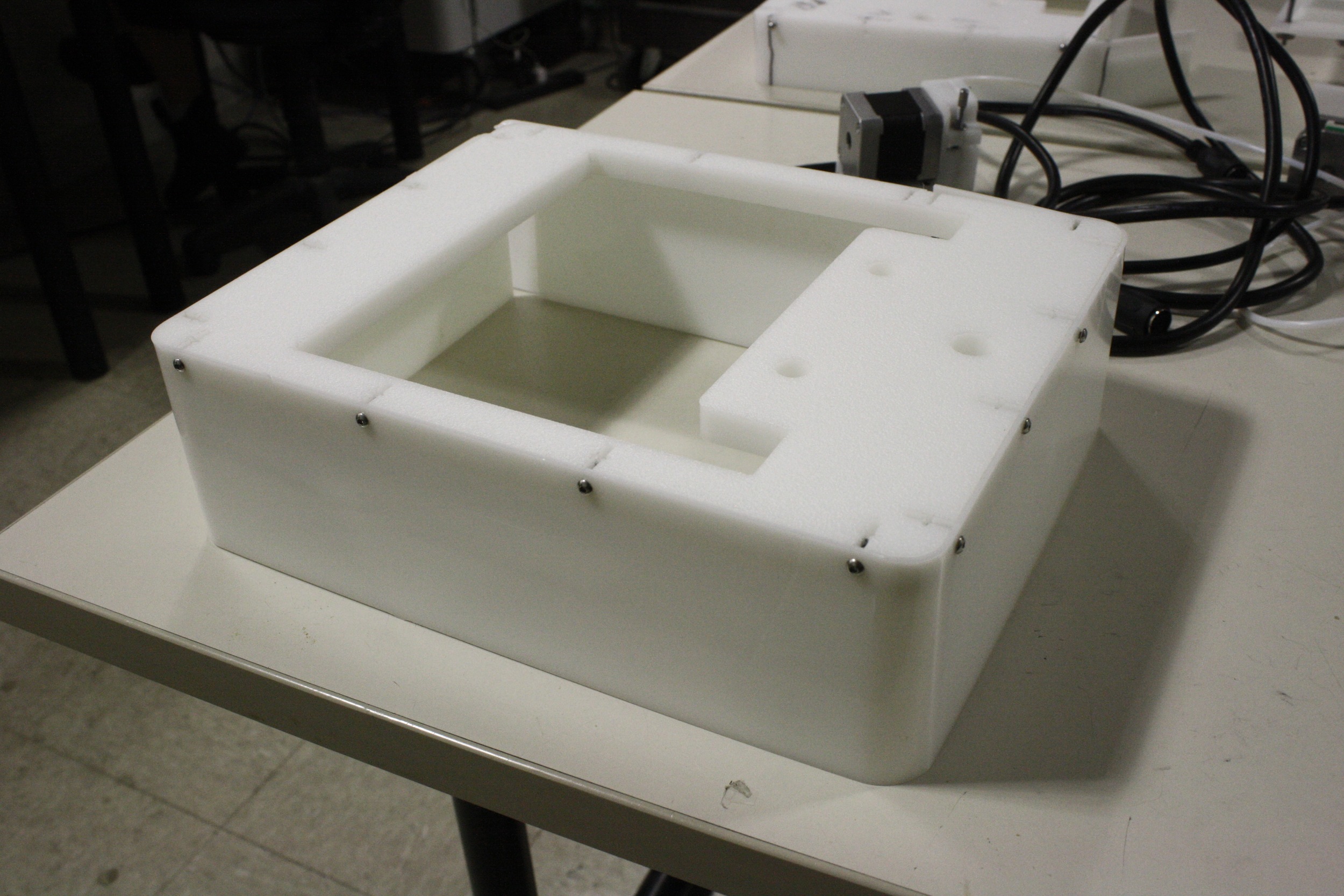

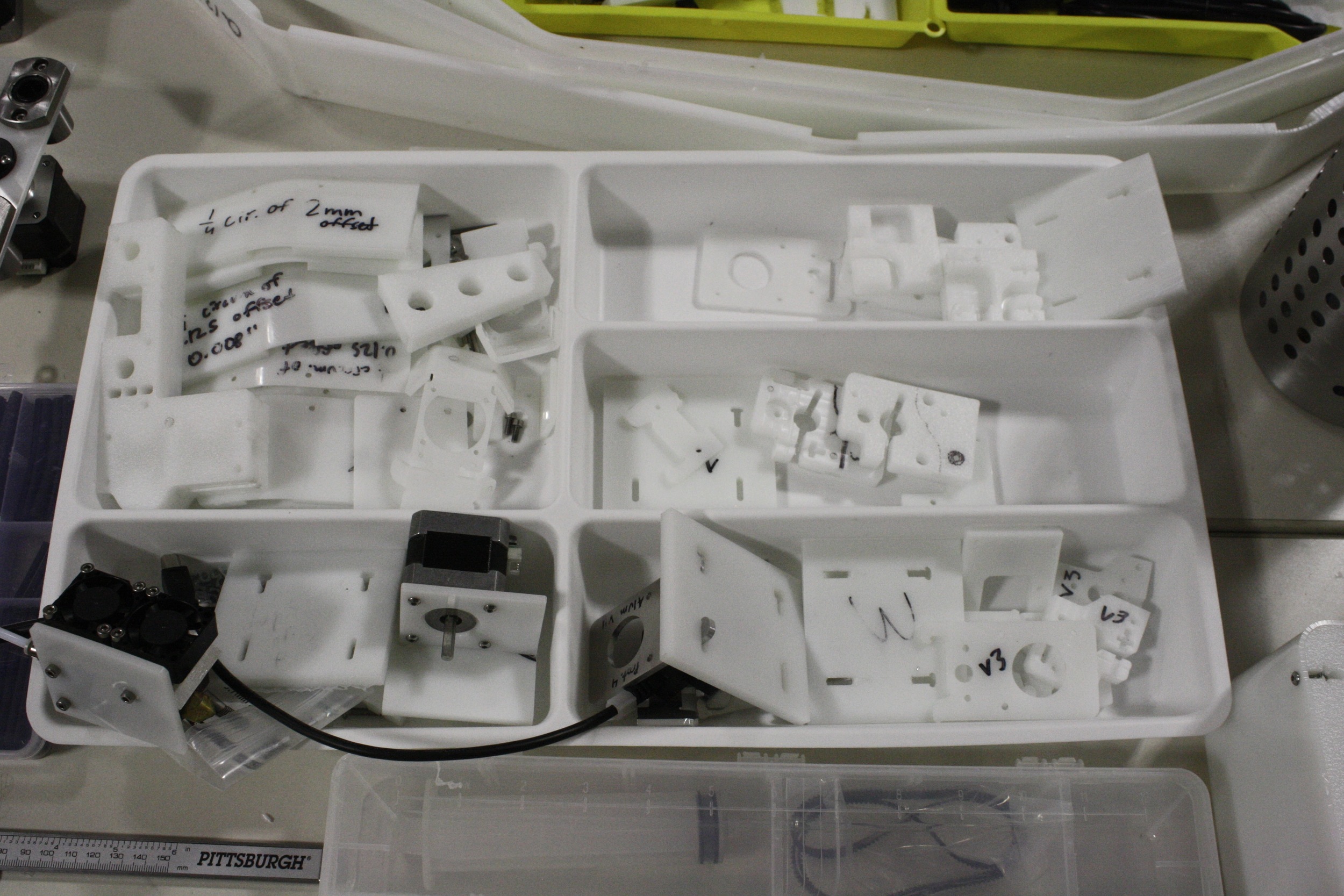

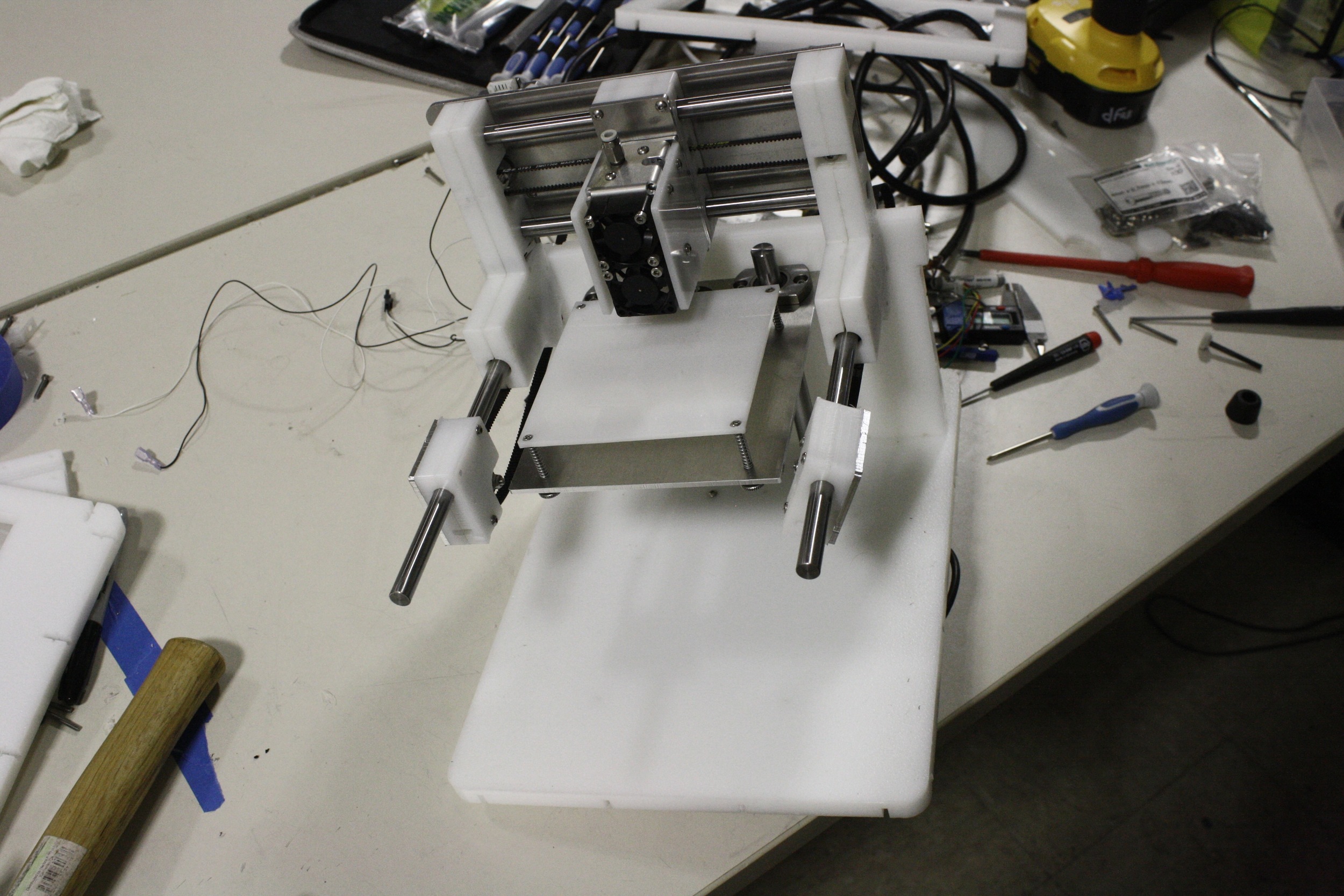

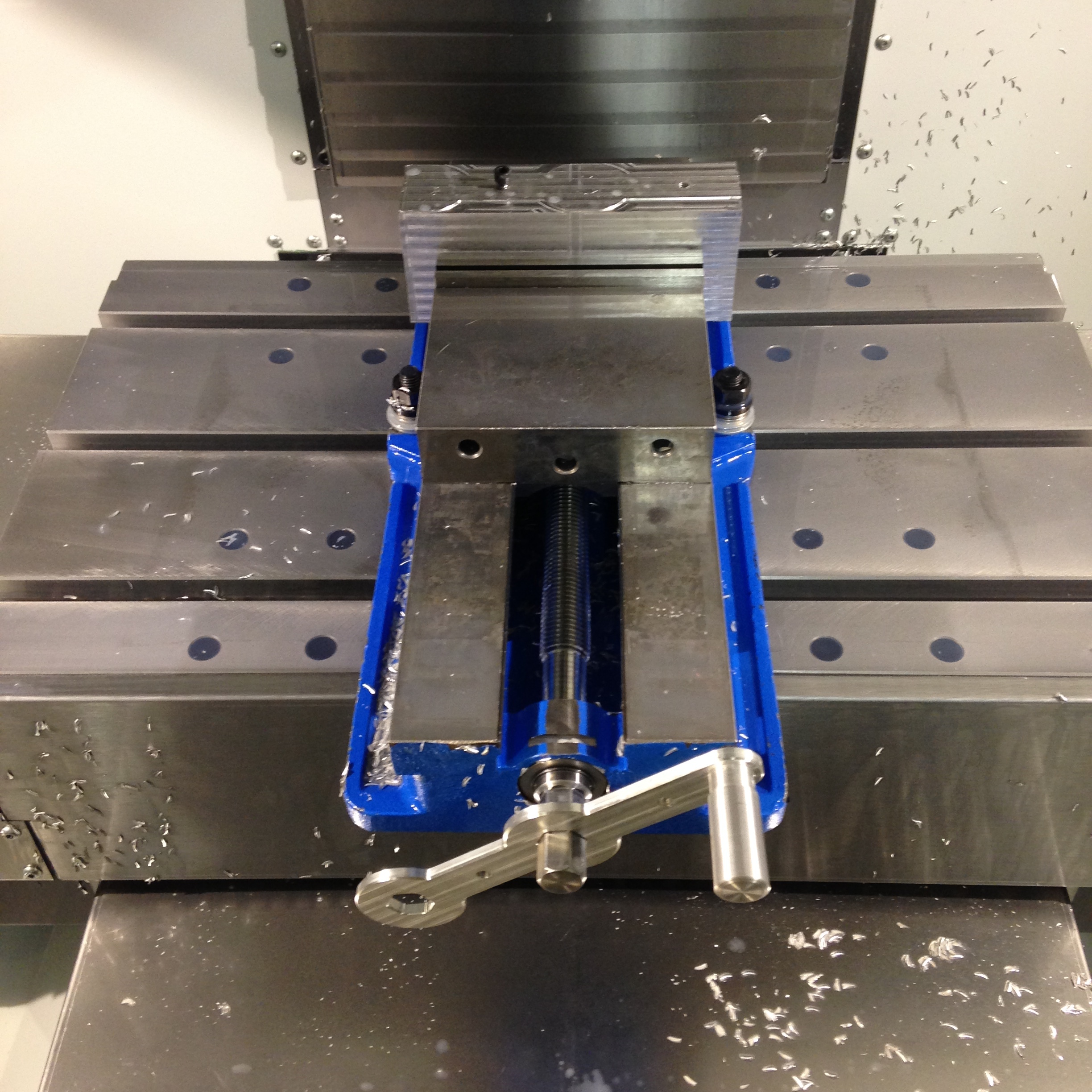

Summer 2015 prototyping

Selections from the Prototyping and DFM process for one of the most recent and most significant design iterations. Much of this documentation involves the CNC machining and fit-testing of parts.

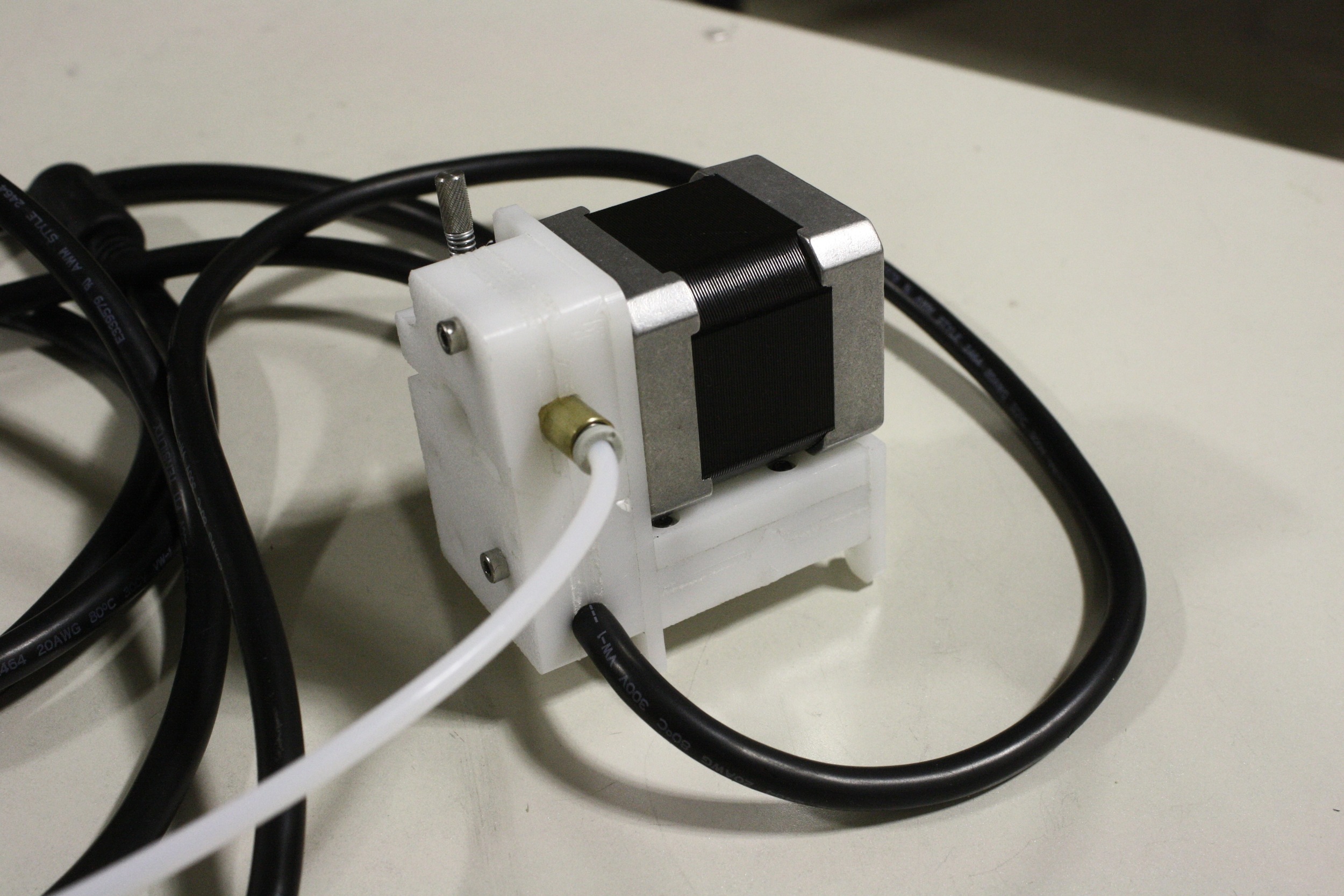

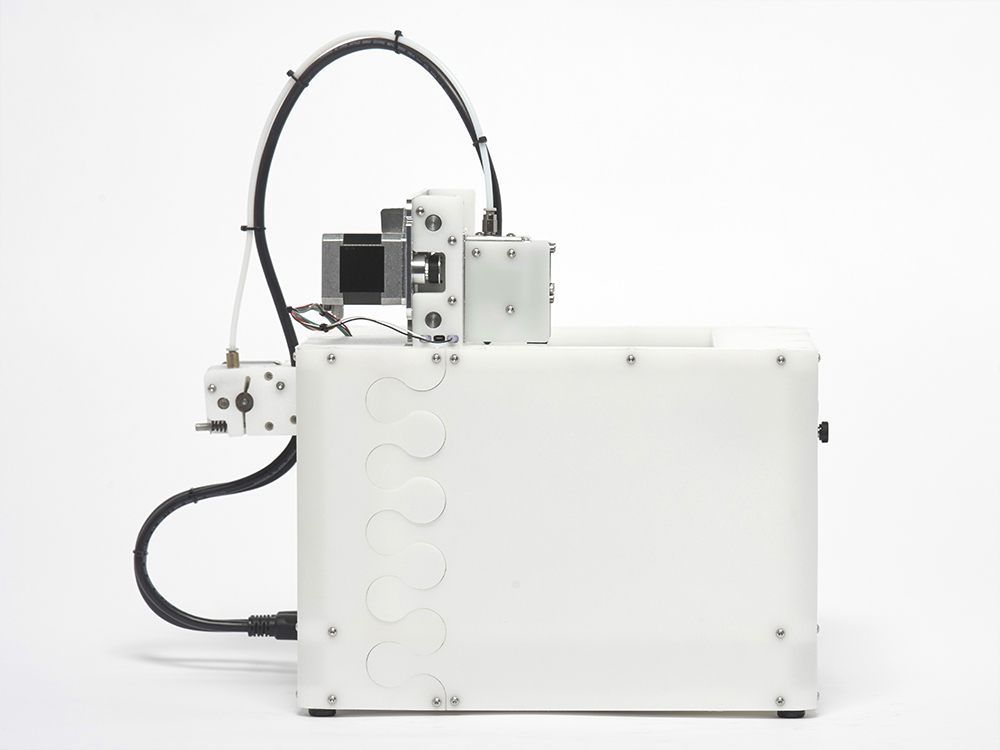

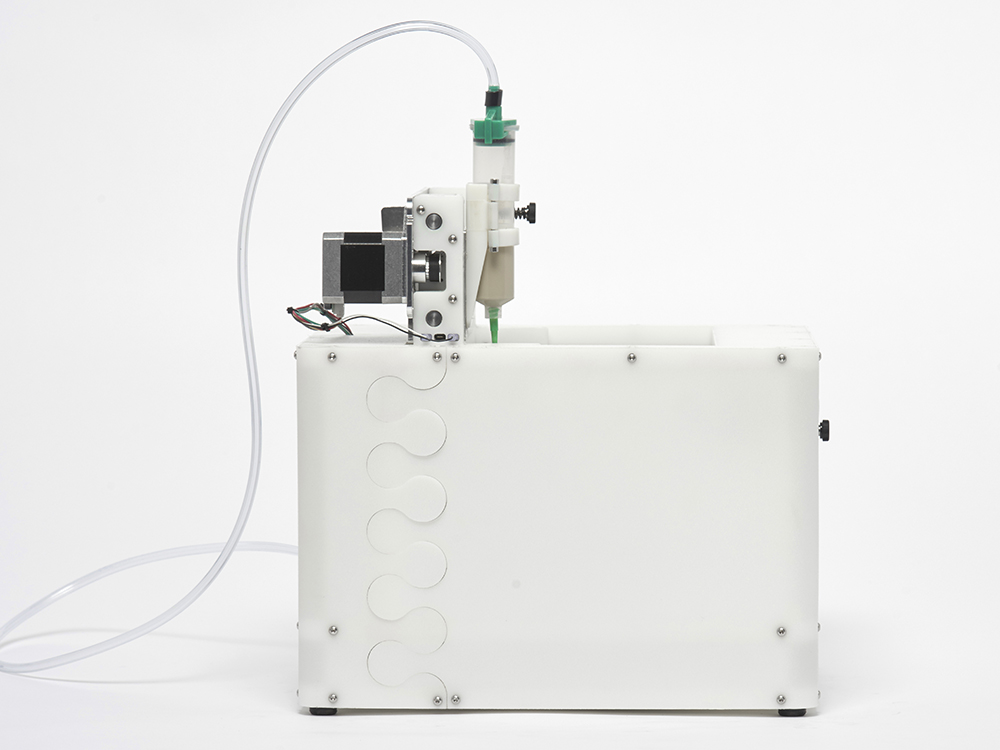

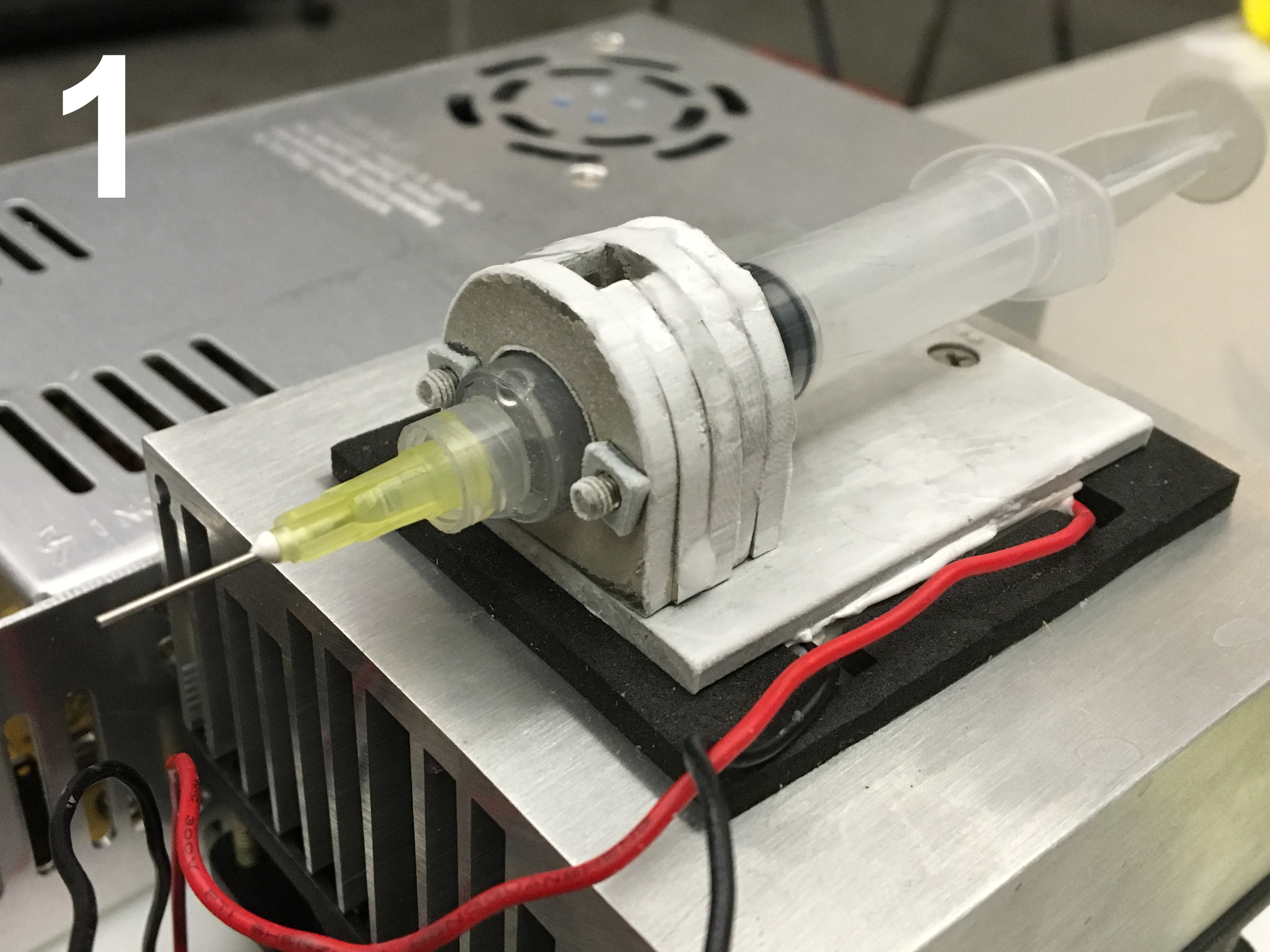

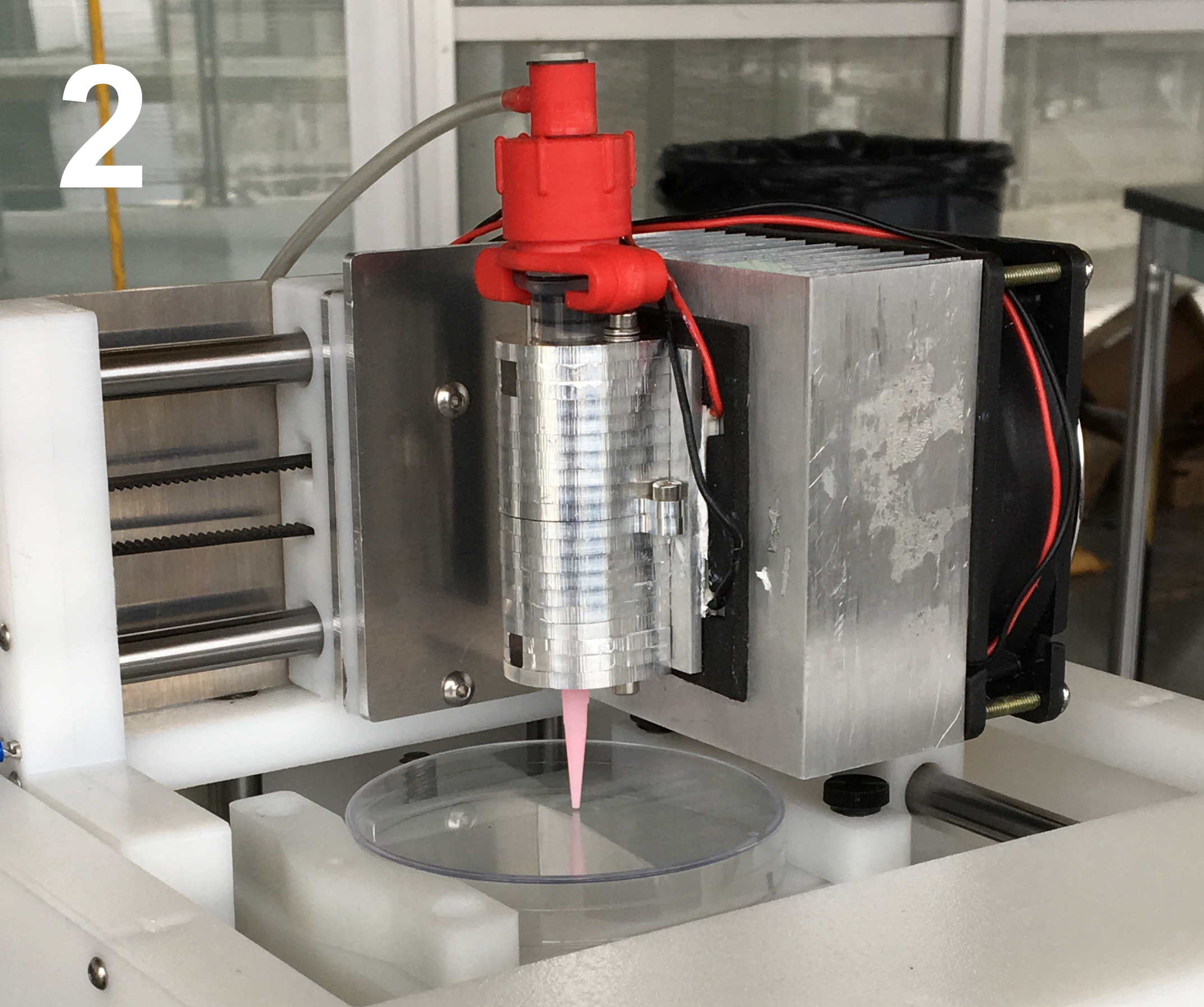

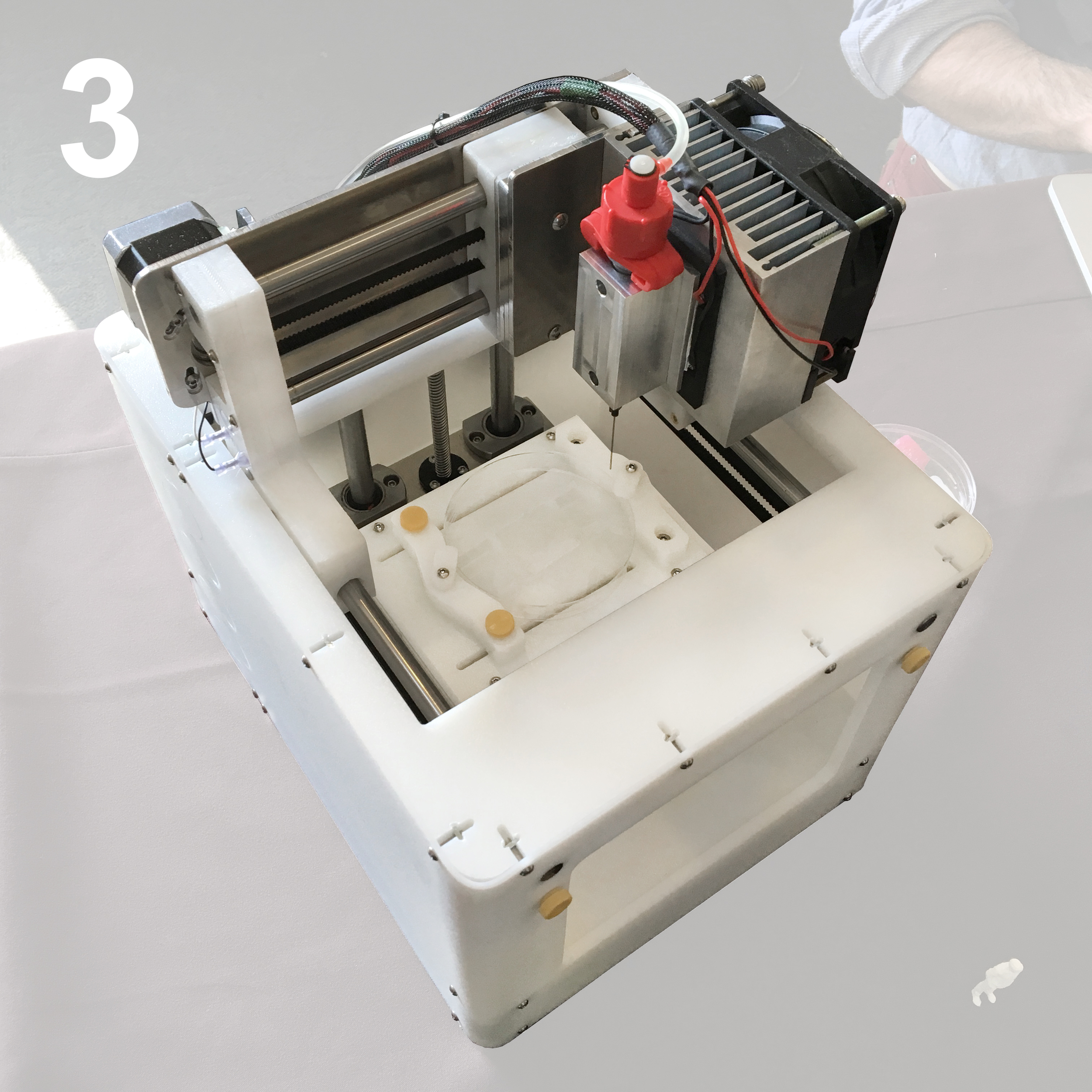

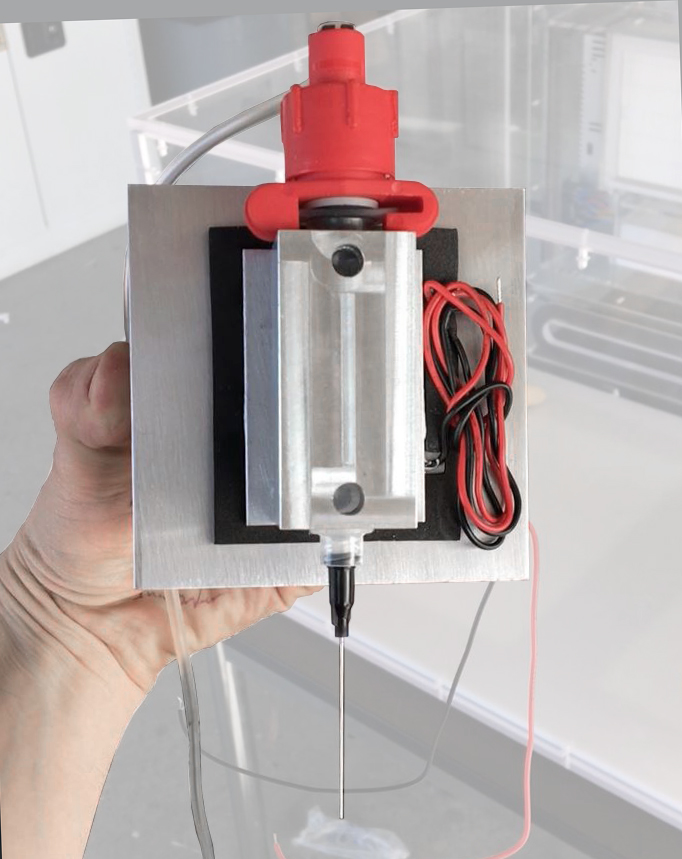

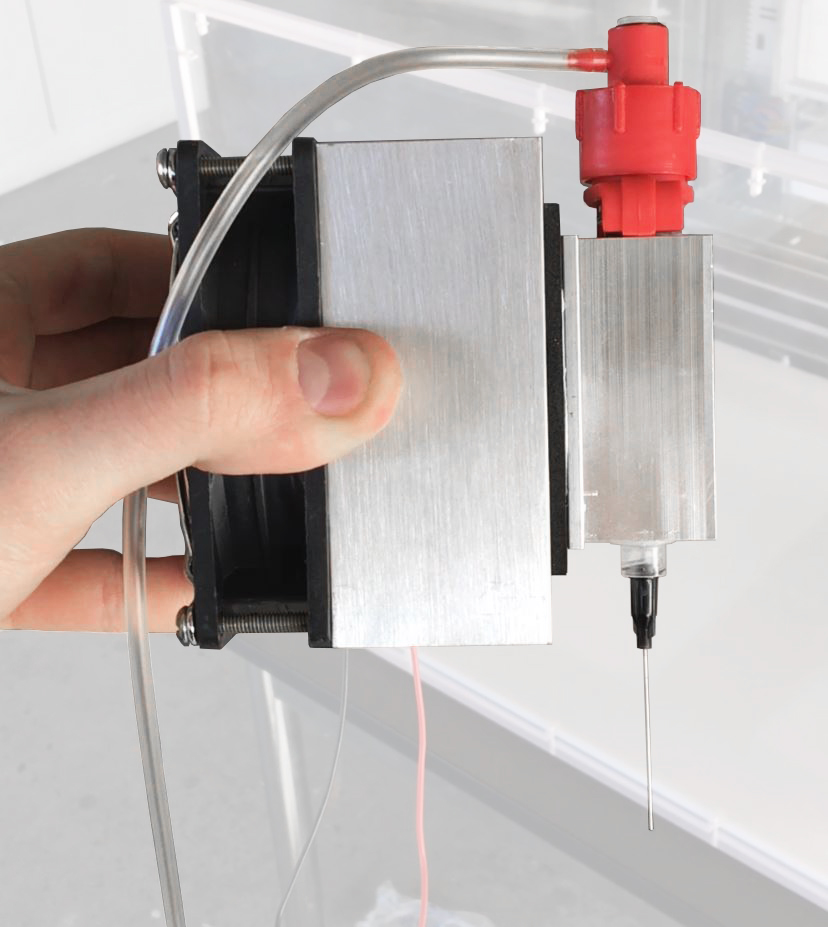

Fall '15 / Winter '16 Bio Printing Hardware Development

The below images highlight some recent development of bioprinting tools.